Introduction

Comparing cargo lift prices is harder than it looks—there are so many variables to juggle: capacity, travel height, design, features, installation complexity, geography, service plans. In this piece, we dive into real‑world data (2025 surveys and supplier quotes), map out price brackets, compare hydraulic vs traction vs MRL types, and show where Tuhe Lift fits in as a high‑value alternative.

Price Ranges by Cargo Lift Type & Capacity (with Tuhe Product Categories)

| Load Capacity (kg) | Lift Type | Typical Price Range | Notes |

|---|---|---|---|

| 500–1,000 kg | Scissor Cargo Lift | $5,000–12,000 | Great for low-rise loading docks or warehouses |

| 1,000–3,000 kg | Guide Rail Cargo Lift | $10,000–30,000 | Flexible height; widely used in industrial sites |

| 3,000–5,000 kg | Traction/Hydraulic Freight | $30,000–70,000 | Multi-floor logistics and warehousing |

| 5,000 kg+ | Heavy-duty Freight Lift | $70,000–150,000+ | For vertical transport in factories or ports |

The actual quotation needs to be consulted with the supplier.

Note: Tuhe Lift specializes in both Guide Rail Cargo Lifts and Scissor Cargo Lifts, each offering distinct benefits in terms of structure, cost, and application. We’ll explore this more deeply below.

What Drives Cost Up or Down? (Scissor vs Guide Rail Lift Comparison)

Among the most common types of cargo lifts used in warehouses, factories, and mezzanine floors are:

• Scissor Cargo Lifts

These use a crisscross scissor mechanism to lift platforms vertically. They are ideal for short vertical travel (1–3 meters) and are cost-effective solutions where a shaft is unnecessary. Tuhe’s scissor lifts typically range from $5,000 to $12,000, depending on capacity and platform size.

Pros:

Lower installation cost

Ideal for ground-floor or low-rise loading

Compact design and quick setup

Limitations:

Limited lifting height

Requires more ground space due to horizontal scissor spread

• Guide Rail Cargo Lifts

More versatile than scissor lifts, these are designed for higher vertical lifting (up to 20 meters or more) and can carry loads from 500 kg to 5,000 kg or more. Tuhe’s guide rail lifts are often used in factories, warehouses, and freight depots.

Pros:

Multi-floor vertical transport

Suitable for high-rise logistics

Can be installed indoors or outdoors

Limitations:

Slightly higher initial cost

Requires shaft walls or frame structure

Fun Fact: Tuhe’s guide rail models can be custom-built to include anti-fall safety valves, PLC control, and full-mesh enclosures, making them ideal for sensitive goods or complex warehouse environments.

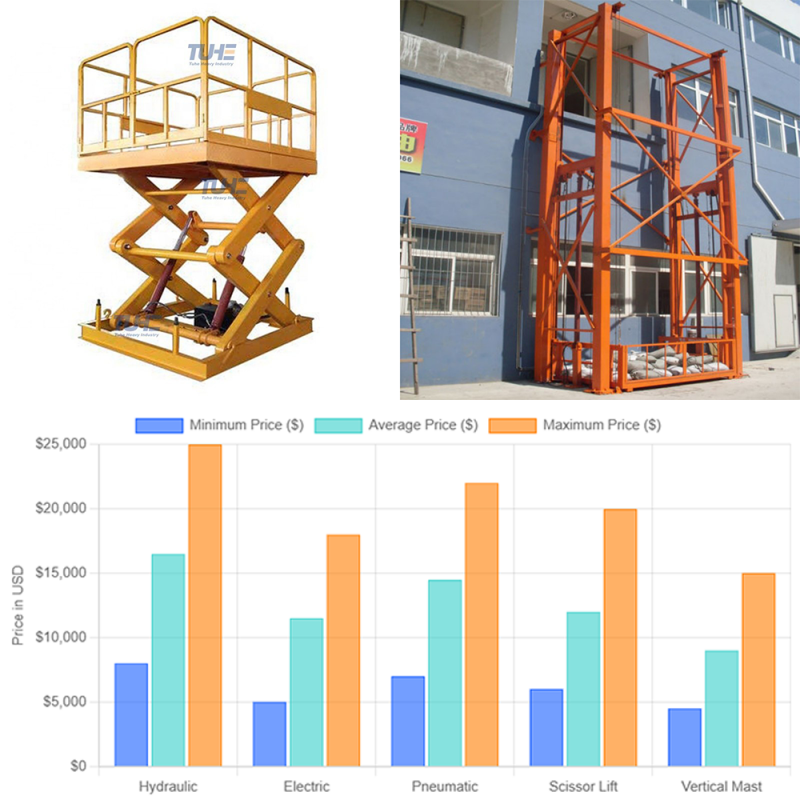

Comparing Supplier Data: Market Overview & Guesstimates

Most global industrial lift providers quote full systems in the mid‑$30k to $75k range for multi‑stop, 2–3 ton lifts. For instance, BDFUJI cites 2025 “one‑stop delivery” costs of $34,500–75,900 for 2–3 ton, 3–5‑floor models. Fujielevator logs higher ranges ($65k–75k) for high‑capacity, multi‑level freight lifts.

On the low end, mobile scissor lifts (not full freight elevators) cost $1,700–7,000 depending on height and capacity. Contrast that with industrial cargo lifts capable of 5–10 tons—modular hydraulic units already pair at $2,600–2,800 for small capacity carts (though these are more like lift‑tables than full elevator systems).

Where Tuhe Lift Meets Market Needs (Updated with Product Types)

Tuhe Lift, founded in 2012 in Jiyang, offers a wide range of cargo lifting solutions, including Guide Rail Cargo Lifts and Scissor Cargo Lifts—both engineered for specific industrial scenarios.

Tuhe’s Scissor Cargo Lifts:

Price Range: $5,000–12,000

Best for: Loading bays, vehicle docks, pallet stacking

Features: Compact, rugged, low maintenance

Ideal for: Customers needing surface-level loading or ground-level elevation

Tuhe’s Guide Rail Cargo Lifts:

Price Range: $10,000–30,000

Best for: Multi-floor transport, warehouses, industrial platforms

Features: Customizable height, platform size, and safety features

Ideal for: Businesses with mezzanine floors or vertical logistics

Both models are backed by Tuhe’s 1-day design turnaround, 7-day global delivery, and 1-year full warranty. What sets Tuhe apart isn’t just the price—it’s the speed, customization, and factory-direct support.

Safety and Standards: A Hidden Cost Driver

While initial cargo lift prices vary by structure and load, compliance with local safety standards—such as CE in Europe, ASME A17.1 in North America, or ISO certifications—can raise costs but dramatically improve long-term reliability. Tuhe Lift ensures all guide rail and scissor cargo lifts comply with international certifications like CE and SGS, making global export and operation smoother. Features like anti-fall protection, limit switches, manual emergency lowering, and safety interlocks are standard on most models. That’s not just a technical bonus—it’s a legal requirement in many jurisdictions and a cost-saving choice when factoring inspections and downtime risks.

Energy & Sustainability Considerations

With rising energy prices and increased environmental regulation, more buyers are now factoring energy consumption into their cargo lift selection. Tuhe’s hydraulic lifts are engineered with low-noise motors and optimized power units, helping reduce consumption during idle and standby states. In regions where green building certifications (like LEED or BREEAM) apply, selecting energy-efficient cargo lifts can be crucial. Tuhe is also experimenting with solar-assist hybrid systems for small-load scissor lifts—particularly useful in rural or off-grid facilities. As energy regulations tighten globally, energy efficiency will likely shift from “nice-to-have” to “non-negotiable.”

Customization: Building Exactly What You Need

Every cargo handling situation is different—space constraints, height clearances, load profiles. That’s where customization becomes more than just a buzzword. Tuhe Lift supports modular engineering, allowing clients to choose platform sizes, lifting height, control systems, materials (e.g., stainless steel vs. carbon steel), and enclosure types. Whether you need a two-post open platform for cartons or a fully enclosed, multi-level food-safe cargo system, Tuhe’s in-house design team provides tailored solutions within just one business day. This “design-to-deliver” flexibility can save clients weeks of engineering delays or retrofits—ultimately lowering project cost and risk.

Total Cost of Ownership: A Comparative Table

Example Purchase + 5‑Year Ownership Costs (approximate)

| Supplier / Lift Type | Initial (incl install) | Annual Operating/Maint | 5‑Year Total Cost |

|---|---|---|---|

| Hydraulic cargo lift (2 ton) typical market | ~$35,000 | ~$3,000 | ~$50,000 |

| Traction cargo lift (2 ton) typical | ~$45,000 | ~$2,000 | ~$55,000 |

| Tuhe Lift 2‑ton hydraulic/traction bundle | ~$33,000 | ~$2,500 | ~$45,500 |

Assumptions: Electricity, minimal downtime, standard maintenance, 3–5 stops.

The logical jump: though Tuhe’s upfront price may be slightly lower, faster delivery and compatibility with standard certifications means lower delayed-cost risk, which often counts more than small sticker‑price differences. That’s the kind of subtle advantage that spreadsheets sometimes ignore—but a human buyer notices.

Choosing Smart: Checklist

Clarify capacity and floors—don't over‑spec just “in case.”

Select lift type based on use: hydraulic if low‑rise; traction/MRL for multi‑floor or continuous usage.

Consider materials and features—custom stainless or food‑grade? Safety extras? Factor 20–30% cost.

Compare total cost, not just unit price—including installation, logistics, and maintenance.

Check lead time and after‑sales service—Tuhe’s 1‑day design and 7‑day delivery may give real advantage.

Factor in certifications and compliance—CE/SGS from suppliers like Tuhe ensures global shipping and permits.

A Slight Detour: Real‑World User Thoughts

One Reddit thread about hoisting services (not exactly lifts but related) echoed how even small jobs rack up cost quickly: operators spending hours, rental of heavy gear, logistics; sometimes $950 for a few pieces of furniture is “reasonable” considering mobilization effort. It’s a microcosm: moving physical things vertically has overhead you might not guess at first.

Conclusion

Cargo lift price comparison is not just about quotes. It's a mosaic of capacity, type, materials, hidden installation expenses, lead times, service levels, and lifecycle costs. Tuhe Lift, founded in 2012 by six senior engineers in Jiyang, offers an attractive value proposition across mid‑range cargo lifts: solid quality, international certification, OEM flexibility, and speed. For standard 2–3 ton applications, you can expect full systems around $30,000–45,000 with lifetime value roughly 10–20% below typical market offers.

If you need to order a Cargo lift, please contact Tuhe lift.

222.webp)

660.webp)

503.webp)

695.webp)