![]() 8m Scissor lift configuration list.pdf

8m Scissor lift configuration list.pdf

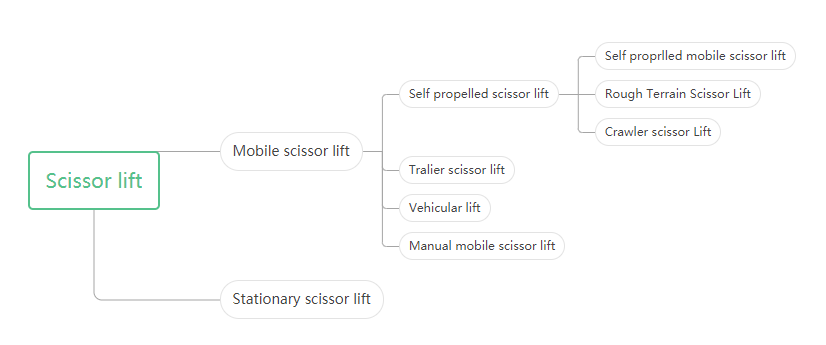

Scissor lift.

A work platform that can only move in a vertical plane, on which people, equipment and materials can be raised for work”

Unlike the boom lift, the scissor lift, it has no telescoping or swivel capabilities.

The unit lift mechanism is a folded support using an "X" cruciform connection.

Mobile scissor lift

Let's first understand the mobile scissor lift, and let's first understand the self-propelled type. This model usually has a power unit that allows the lift to move, so that the lift can perform work in different workplaces and can be quickly deployed to the workplace.

Among them, according to different workplace and moving speed requirements, it can be divided into self-propelled type, trailer type, vehicle type and manpower mobile type.

1. Self-propelled scissor lift:

This is the most common scissor lift model, which can be quickly and maneuver-ably deployed within a certain working area. There are 3 common types,

1) Hydraulic wheeled self propelled scissor lift, which is often deployed inside and outside the building, or close to the building, and can move a certain distance to change the working place. However, it is required that the ground of the workplace must be a level hardened road surface. In terms of size, it can also be divided into regular models and mini models. (The mini model is mainly for indoor use, with access to elevators and doors)

2) Rough Terrain Scissor Lift, which is often used in situations where the outdoor working ground is relatively rugged. It has strong adaptability to the workplace and relatively low requirements for the working environment, suitable for outdoor use. Provides more power for operation in harsh outdoor environments.

They are typically powered by burning diesel, gasoline or LPG engines to provide the power needed to operate over rough terrain and lift heavier payloads.

3) Crawler scissor lift, which is mainly required to adapt to muddy roads or need to cross sloped roads. Able to work in places where wheeled lifts cannot work, and this lift can be equipped with hydraulic outriggers that are leveled at the touch of a button, allowing the lift to lift even on slopes.

2. Trailer scissor lift:

This kind of lift has no independent movement hope. Usually, there are two pneumatic tires for auxiliary movement, which can be connected to the tractor through the trailer and move with the tractor. The moving speed can reach 110km/h, and it can be separated from the tractor when it arrives at the work site, and then the lifting operation can be carried out.

3. Vehicle scissor lift:

The lifting structure of the lift is directly installed in the body of the pickup, which can be quickly deployed and put into use. Compared with the trailer type, it is faster and more convenient.

4. Manual mobile scissor lift:

This kind of lift does not have an independent mobile power unit, so it usually requires manual push and pull to make the lift move for a short distance, but we can also install a set of auxiliary walking devices for this type of lift, after all, some models The weight is close to 4500kg, and it cannot be moved effectively by manpower, but its biggest feature is that it is cheap.

There are usually three kinds of power for Scissor lift: AC, DC, diesel

1.AC: It is necessary to have a power supply in the workplace, and the power supply needs to be stable. So by doing work around inside and outside the building. More limited.

2. DC: That is, the lift has its own power supply, and the operation is powered by batteries, which greatly expands the scope of use of the lift, and is no longer limited by the power source like the AC powered lift. Electric scissor lifts powered by batteries rather than internal combustion engines are more environmentally friendly.

Since there are no exhaust emissions or loud noises during operation, they are ideal for indoor operation. Electric scissor lifts are generally smaller, less bulky and have narrower platforms than diesel powered lifts. Since they operate indoors, the units are often equipped with non-marking tires to prevent damage to the floor during operation.

3. Diesel Power: Diesel powered scissor lifts are powered by conventional diesel engines. They are not as environmentally friendly as their electric counterparts, as they are noisy when running and emit dirty exhaust fumes.

Diesel-powered scissor lifts are typically equipped with larger platforms and are recommended for operation in outdoor construction projects, well-ventilated indoor spaces, and where engine noise will not distract or interfere with vital communication between employees.

Features of scissor lift

There are many benefits to using a scissor lift in construction and other projects.

1) Access to high places and hard to reach areas

The scissor lift with a lift height of 3- 18m enables workers to reach heights that would otherwise be inaccessible. Workers may have difficulty accessing areas to complete maintenance, repairs or cleaning.

2) Easy to use

Scissor lift controls are simple and straightforward, and operators can be trained in a relatively short period of time. According to the attached operation manual, the lift can be quickly operated and standardized.

3) Scissor Lift has compact size

Scissor lifts are the most compact elevating work platforms. Due to their compact size, they can be used in tight spaces with restricted access. It is also very convenient to store in the warehouse, saving space.

4) Multiple choices

According to different operation requirements, different types of scissor lifts can be used, which provides great flexibility for the choice of aerial work.

5) Scissor Lift has high safety

Scissor lifts provide a safe and convenient way to lift items to the desired height. At the same time, scissor lift has a large table and load, which can prevent workers from carrying tools and maintenance parts by themselves when working at high altitudes, which reduces the workload of workers, and also has a series of safety guarantees such as safety guardrails, which greatly reduces workers Dangerous potential during work.

Stationary scissor lift

The same is the "X" structure, this kind of lift people prefer to classify it as cargo lift, because it is usually used as cargo lift in factories, warehouses shopping malls, docks, airports and other places to lift goods. This type of scissor lift has a larger load, ranging from 100kg to 100ton, and the platform can also be 100% customized according to the workplace.

At the same time, this type of scissor lift can also be customized into a car parking lift, which can effectively save space in your yard or garage.

There is also a scissor lift - trolley lift table. This lift is more used to lift some small-quality goods, 100kg-2000kg, and the lifting height is also very limited, 800mm-2000mm, but it is a warehouse and logistics company. A good helper, very practical, adhering to the compactness of scissor lift, it only takes up a small space after folding, can be placed in the truck bed and your garage, and can be taken out for use when needed.

How to complete the production of a scissor lift?

How to produce a scissor lift, first of all, we need to understand the components of scissor lift, which usually consists of three parts, the bottom body, the middle support frame, and the upper platform.

The bottom body adopts an integrated structure, the control system, power system and safety protection system are all protected in the metal protective shell, and all metal parts are treated with anti-rust and anti-corrosion to ensure that the electrical components at the bottom of the lift can work stably.

The middle support frame is processed with high-quality steel to ensure the safety and service life of the lift. At the same time, there are limit switches and anti-fall devices in the middle of the support. The brackets are attached via maintenance-free pivot pins.

On the upper platform, there are safety guardrails and safety ropes to protect the safety of the staff, and the surface of the platform is treated with anti-skid treatment. A controller is also configured on the upper platform to allow workers to operate the lift efficiently.

These parts are uniformly produced by the factory's production line, and each part is precisely cut and welded according to modeling and data, and then treated with anti-rust and anti-corrosion treatment.

After the production of these three main bodies is completed, they will be assembled by professional technicians, and the integrity and reliability of the parts will be ensured at every step of the assembly. Grinding and polishing and anti-rust treatment are carried out for the places that need to be re-welded.

After assembly, it does not mean that the production of scissor lift has been completed, and the scissor lift must be tested many times. Make sure that the scissor lift can run well without any faults. After all the tests are over, a qualified scissor lift will be considered production.

How to customize a scissor lift?

Sometimes the standard models produced by our factory do not fit well with users, but as a manufacturer, we can customize them according to your requirements. The first is the color, we can provide you with the color you like according to your preference.

Of course, it also includes customizing your own logo for you.

Platform, we can customize the size of the platform for you, or add a retractable table top for you, or install various equipment you need on the platform.

The load can be customized according to your requirements, under the models of different heights.

As a manufacturer, we will try our best to produce a scissor lift that satisfies you according to your requirements.

How to buy a scissor lift?

First of all, we can choose a scissor lift according to our job needs. You can choose according to the characteristics of the different types of scissor lift mentioned earlier. This is one of our selection criteria, of course, the price is also a very important reference factor, after all, some types of scissor lift are very suitable for your job requirements, but the price is beyond your expectations. So I have listed the prices of some scissor lifts here for reference.

Self propelled mobile scissor lift | 5000-15000 USD |

Rough Terrain Scissor Lift | 12000-70000 USD |

Crawler scissor Lift | 5000-40000 USD |

Trailer scissor lift | 3000-10000 USD |

Vehicle-mounted scissor lift | 4500-16000 USD |

Manual mobile scissor lift | 2000-15000 USD |

According to your work requirements and budget, after choosing a scissor lift that suits you, you can confirm the order with your supplier.

Usually after all preliminary discussions are over, a deposit is paid to the seller to confirm the order. This deposit is usually 30% or 50% of the total order amount, which can be reached through discussions between the two parties. After the supplier receives the deposit, they can start the production of scissor lift. After the production is over, the seller can arrange the transportation after paying the remaining payment before delivery. If there is stock, you can also pay 100% of the order amount. Ships later.

When the goods arrive at the port or the place you specify, it is the shipment of scissor lift, which is very important.

When using a crane or forklift to lift the machine, keep normal judgment and plan to control the movement of the machine.

l Transport vehicles must be parked on level ground.

l When loading the machine, the transport vehicle must be fixed to prevent rolling. Make sure that the vehicle capacity, loading surface, belt or rope is sufficient to support the weight of the machine (refer to the “Specifications” section).

l The machine must be in a horizontal plane or securely fastened before releasing the brakes. Fixed to truck or trailer when transported the machine wheels should always be locked when preparing for transport.

Secure the machine to the transport surface by driving the fastening points on the chassis.

Use a chain or belt with sufficient load strength.

Turn the key switch to the OFF position and remove the key before shipping.

Thoroughly inspect the machine to prevent loose or unsecured parts.

Then you can operate the lift according to the operating manual.

How to maintain scissor lift after use?

Monthly Maintenance

When the lifting platform is in the rising state, the-internal maintenance of the lifting platform shall be carried out. The lift table shall be hung up to prevent the lifting platform from descending and causing casualties.

A. Check lubrication and wear of roller, intermediate shaft and bearing, cylinder, shaft and bearing, arm hinge shaft and bearing, etc.

B. Lubricating oil is added to the above parts to extend the service life of the bearing.

C. Check hydraulic oil quality and oil level. Lifting platform to the highest hydraulic oil level should be higher than the tank bottom 40-50 mm. When the color of the hydraulic oil is dark, the oil is sticky, or the oil is made of sand and gravel, the hydraulic oil should be replaced in time. The hydraulic system of the lifting platform should apply 32# hydraulic oil.

Annual Maintenance

A. Check the connecting parts of hydraulic pipe and pipe. Replace the damaged pipe immediately: tighten the joint if the connecting part is loose.

B. Remove and disassemble the descending valve, blow the valve core clean with compressed air and reinstall.

C. Drain all the hydraulic oil in the oil tank, open the oil tank, take out the oil absorption filter, wash it, put it back into the oil tank, and install it according to the original taste. Fill the tank with new oil .

As a professional scissor lift manufacturer, TUHE has more than 10 years of technical experience, and is now committed to innovation and development. The MOQ of all models of scissor lift is a minimum order. In addition, we are also actively looking for Our agents, when the willingness is reached, we will discuss and sign an agency agreement with the agent. In addition, agents can also enjoy more services provided by our company.

1. We will freely offer construction drawing and design for the distributor.

2. In order to support the distributor’s sales, we will provide product brochures for the distributor.

3. If the distributor faces any difficulties during installation and maintenance process of the lift, we will offer to solve the issues for the distributor immediately.

4. We will pick up the distributor from the airport and should provide a hotel stay for the distributor.

5. We will provide accommodation If the dealer sends someone to our factory to study.

FAQ

1. What is a scissor lift, and what are its applications?

A scissor lift is a type of mobile elevated work platform that consists of a platform supported by folding crisscrossing supports,

known as scissor mechanisms. It is commonly used in construction, maintenance, warehousing, and other industries to provide

temporary access to elevated areas.

2. What factors should I consider before purchasing a scissor lift?

Before purchasing a scissor lift, consider factors such as the required working height, platform size, weight capacity, power

source (electric, diesel, or hybrid), indoor or outdoor usage, and any specific features needed for your application.

3. How do I determine the right lift capacity for my needs?

To determine the appropriate lift capacity, consider the weight of the operators, tools, and materials that will be on the

platform simultaneously. Ensure that the lift's weight capacity exceeds the total weight to maintain safety and efficiency.

4. Should I opt for a new or used scissor lift?

The decision to choose between new or used scissor lifts depends on your budget and specific requirements. While new lifts

offer the latest technology and come with warranties, used lifts can be a cost-effective option if they meet safety standards

and are in good condition.

5. What safety features should I look for in a scissor lift?

Safety is paramount when selecting a scissor lift. Look for safety features such as platform guardrails, emergency stop buttons,

tilt sensors, non-slip surfaces, and safety interlocks that prevent unauthorized operation.

6. How can I ensure compliance with safety standards and regulations?

Ensure the scissor lift meets relevant safety standards and regulations, such as ANSI/ITSDF and CE certifications. Additionally,

provide proper operator training to ensure safe operation and compliance with local regulations.

7. Can I customize a scissor lift to suit my specific needs?

Yes, many manufacturers offer customization options to tailor the scissor lift according to your specific requirements.

Customizations can include platform size, additional features, special coatings for outdoor use, and more.

8. What are the maintenance requirements for a scissor lift?

Regular maintenance is essential to ensure the safe and efficient operation of a scissor lift. Follow the manufacturer's

maintenance schedule, conduct periodic inspections, and address any repairs promptly.

9. Should I consider renting a scissor lift instead of purchasing one?

Renting a scissor lift can be a viable option for short-term projects or when occasional access to elevated areas is required.

Rental allows you to avoid upfront costs and ongoing maintenance expenses.

10. How do I choose a reliable supplier or dealer for the scissor lift?

Choose a reputable supplier with a track record of providing quality products and excellent customer service. Check

customer reviews, certifications, and warranty offerings before making a decision.

Remember, a well-informed procurement decision ensures you get the right scissor lift for your needs, enhancing

workplace efficiency and safety.

If you have any questions about scissor lift, please let us know, we will answer you as soon as possible, if you are considering buying a scissor lift, we will provide you with guidance, as a manufacturer we will also give you the best

price. Inquiries are welcome.

222.webp)

660.webp)