Hydraulic car lifts—those hulking platforms that seem to defy gravity—are the silent heroes in auto shops, car showrooms, and even in some high-end home garages. But have you ever paused to ask: how does a hydraulic car lift really work? Is it all about brute mechanical force, or is there a refined science beneath those steel arms?

In this article, we’ll unpack the core mechanics of hydraulic lifts, discuss why they’re essential in the automotive world, and explore how companies like Tuhe Lift are raising the bar with advanced engineering, tailored service, and global ambition.

The Fundamental Principle: Pascal’s Law in Action

To understand a hydraulic lift, we first need to revisit a 17th-century French mathematician—Blaise Pascal. His namesake law forms the beating heart of all hydraulic systems.

Pascal’s Law states:

"A change in pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and to the walls of its container."

In layman’s terms: if you apply pressure at one point in a fluid-filled system, that pressure is evenly distributed everywhere. That’s the magic sauce behind hydraulic lifting.

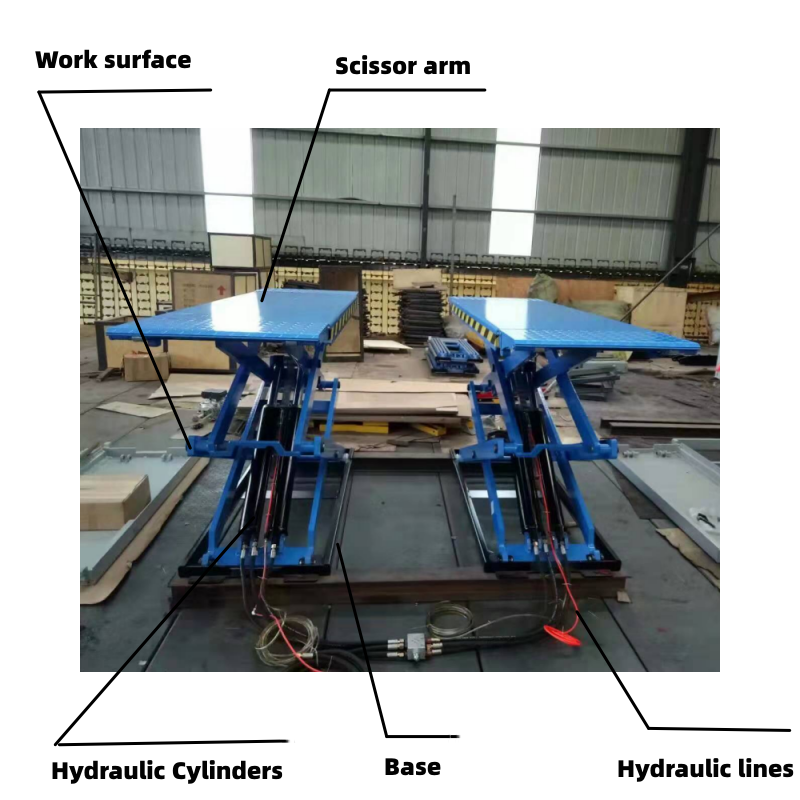

Components of a Hydraulic Car Lift

Let’s break down the basic anatomy of a typical hydraulic car lift:

| Component | Function |

|---|---|

| Hydraulic Cylinder | Houses the piston that pushes the lift upward |

| Pump | Sends hydraulic fluid into the cylinder |

| Reservoir | Stores hydraulic oil |

| Control Valve | Regulates fluid direction and pressure |

| Lift Arms/Platform | The structure that supports the vehicle |

| Safety Locks | Prevents accidental lowering or collapse |

Each part plays a vital role, but the interaction between hydraulic fluid, pressure, and piston movement is where the real action happens.

The Step-by-Step Lifting Process

Still wondering how exactly the vehicle rises? Here’s a simplified breakdown:

The motor activates the hydraulic pump.

The pump forces hydraulic oil into the cylinder.

Pressure builds inside the cylinder, pushing the piston upward.

The piston lifts the platform (and the car) into the air.

Safety locks engage at desired heights for protection.

Lowering the car is just as elegant. By reversing the pump flow and releasing pressure, the lift descends smoothly, aided by gravity and the controlled movement of oil back into the reservoir.

Why Hydraulic Over Mechanical? Let’s Look at the Data

When comparing lift technologies, hydraulic systems often win in simplicity, power-to-weight ratio, and space efficiency.

| Parameter | Hydraulic Lift | Mechanical Lift |

|---|---|---|

| Load Capacity | Up to 50,000 kg | Typically under 10,000 kg |

| Space Requirement | Compact | Bulky, needs extra counterweights |

| Maintenance Needs | Moderate | Frequent lubrication & tensioning |

| Cost per Unit (USD) | $2,000 – $15,000 | $3,500 – $20,000 |

| Energy Efficiency | Higher at low-speed operations | Less efficient under heavy load |

Data Source: International Federation of Robotics Automotive Equipment Report, 2023

Clearly, hydraulic lifts punch above their weight when it comes to performance and cost.

Tuhe Lift: A Pioneer in Hydraulic Car Lifting Technology

In the hydraulic lift market, Tuhe Lift stands out—not just for its engineering precision but also for its service philosophy.

Company Snapshot: Tuhe Lift

| Founded | 2012 |

|---|---|

| Founders | 6 senior engineers |

| Location | Jiyang, Shandong—China's lifting platform manufacturing hub |

| Workshops | 3 production centers + 1 exhibition hall |

| Employees | 300+ staff, 20 global distributors |

| Certifications | CE, SGS, ISO |

| Markets Served | USA, Germany, Australia, Algeria, Peru and more |

Tuhe Lift has independently developed 6 major lift series, covering over 50 product variants—from compact home lifts to robust scissor and articulated boom lifts.

Their core strength? A high cost-performance ratio combined with global-grade reliability.

Hydraulic Lift Types and Where They Shine

Hydraulic lifts are not all created equal—each type is purpose-built for specific applications. Whether you're working in an industrial warehouse, a multi-level home garage, or a commercial auto repair center, there's a hydraulic lift tailored for the job.

Here’s a breakdown of the most common types, now including Car Lifts, and where each one excels:

| Type | Use Case | Height Range | Lifting Capacity |

|---|---|---|---|

| Car Lift | Auto repair shops, home garages, car parks | 1.2–3 meters | 2–5 tons |

| Scissor Lift | Alignment stations, detailing, underbody work | Up to 2 meters | 3–5 tons |

| Mast Lift | Tight spaces, residential use | 1–1.5 meters | 1–3 tons |

| Articulated Boom Lift | High access tasks, building maintenance | 5–20 meters | 200–500 kg |

| Cargo Lift | Factory floors, logistics hubs | 1–10 meters | 500 kg–10 tons |

| Home Lift | Villas, personal mobility, underground garages | 0.5–2 meters | 150–300 kg |

Spotlight: Car Lifts

Car lifts are arguably the most recognizable type of hydraulic lift, widely used in automotive service centers, showrooms, and increasingly in residential garages. Designed to provide safe, stable elevation of passenger vehicles, they come in multiple configurations such as:

Two-post lifts – Compact and cost-effective

Four-post lifts – Ideal for long-term vehicle storage

Scissor car lifts – Great for underbody access in tight spaces

Underground car lifts – Luxury solution for hidden garages

At Tuhe Lift, we engineer car lift solutions that blend strength, efficiency, and a compact footprint—ensuring smooth operation, low noise, and robust safety features. Whether you're a dealership needing quick turnover or a homeowner wanting to save garage space, Tuhe’s car lifts offer a versatile, durable option that doesn’t cut corners.

How Safe Are Hydraulic Car Lifts?

Hydraulic lifts are inherently safe due to built-in redundancies. Key safety features often include:

Automatic mechanical locks

Pressure relief valves to prevent overloading

Flow restrictors for smooth descent

Emergency stop controls

Anti-surge hydraulic piping

According to a 2022 safety audit by the China National Machinery Safety Board, hydraulic lifts have a failure rate of <0.03% annually, provided proper maintenance is conducted.

Still, routine inspections are non-negotiable.

Energy and Environmental Considerations

While hydraulics are powerful, critics often raise concerns about oil leaks and power consumption. However, innovation has stepped up.

Tuhe Lift, for example, uses bio-degradable hydraulic oil in many models and integrates low-power pumps that reduce idle consumption by up to 30%.

| Feature | Traditional Lift | Tuhe Lift’s Tech |

|---|---|---|

| Oil Type | Mineral oil | Eco-hydraulic fluid |

| Idle Power Consumption | 400W/hr | 280W/hr |

| Leak Detection System | Manual | Smart sensor-based |

| Noise Emission (dB) | 75–80 | Under 65 |

In a world that’s turning greener by the day, these tweaks matter.

The Economics: ROI of Investing in a Hydraulic Lift

Let’s talk money. Is it worth buying a hydraulic lift for a garage or auto business?

Short answer: yes.

| Scenario | Annual ROI Est. |

|---|---|

| Small auto repair garage | 35–45% (via labor saved) |

| Multi-bay auto dealership | 50–65% (via volume handling) |

| High-end home with car elevator | Value increase > $20,000 |

Plus, with Tuhe Lift’s 1-day custom design, 7-day global delivery, and 1-year warranty, the setup timeline and downtime are minimized.

Looking Ahead: What’s Next for Hydraulic Lifting?

The future isn’t just about “lifting heavier.” It’s about smart, connected, and energy-efficient lifting. Here are some trends:

IoT Integration: Lifts with remote diagnostics, maintenance alerts, and performance logs.

AI Load Balancing: Sensors auto-adjust lift pressure based on real-time load.

Compact Home Models: Designed for urban villas and vertical garages.

Solar-powered units: Still in pilot phase but promising.

Tuhe Lift has already begun R&D in AI diagnostics and is piloting a new solar-assisted cargo lift in Southeast Asia. The game is changing.

Final Thoughts: Why Tuhe Lift Deserves Attention

Understanding how a hydraulic car lift works gives you a peek into an elegant fusion of fluid physics, mechanical design, and user-oriented engineering. Whether you're lifting a sedan, a delivery van, or a piece of industrial equipment, the underlying principle remains the same—but the execution? That’s where brands like Tuhe Lift shine.

With over a decade of experience, a world-class team of engineers, and a global footprint, Tuhe Lift isn’t just selling platforms. They’re delivering trust, innovation, and efficiency—lifted to the next level. Contact Tuhe Lift to find the lift you need.

222.webp)

660.webp)

503.webp)

695.webp)