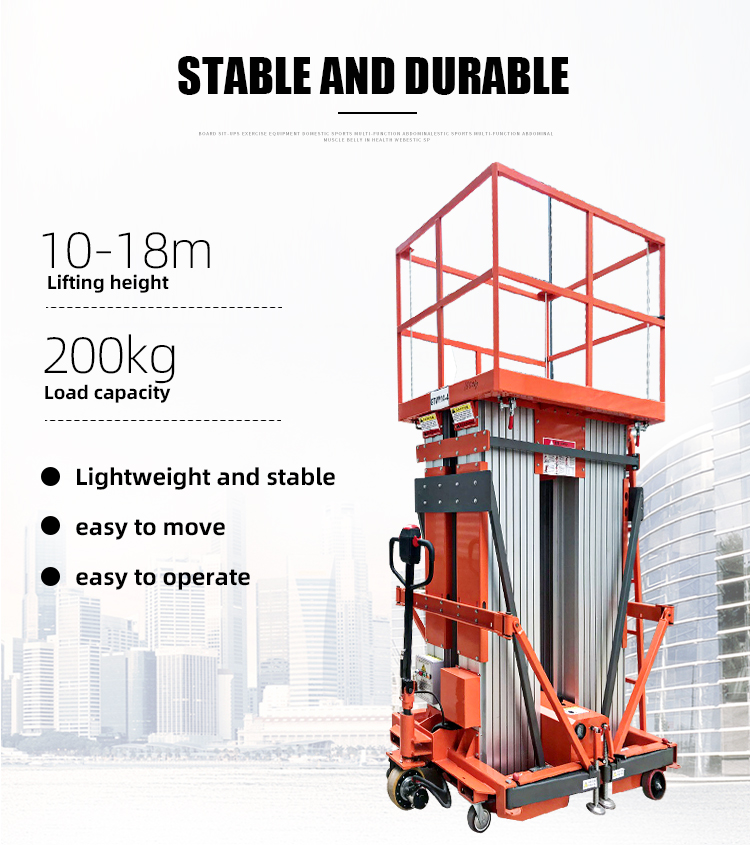

Aluminum Alloy Four Mast Lift

In today's dynamic industrial landscape, finding the right equipment that combines efficiency, safety, and versatility is a game-changer. The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift stands out as a solution that truly takes your operations to the next level. With its impressive working range, high elevation capabilities, and substantial load capacity, this lift is a deserving addition to your toolkit.

Large Working Range

With a substantial height of 14 meters, this lift offers a large working range, allowing your team to access elevated areas with ease, whether you're in construction, manufacturing, or maintenance.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift boasts a remarkable working range, making it a valuable asset in various industries, including construction, manufacturing, and maintenance. Here are some specific details and examples to highlight its large working range:

Impressive Height: At 14 meters (approximately 46 feet), this lift enables workers to reach heights that were previously inaccessible without scaffolding, cranes, or other cumbersome equipment. Consider a scenario where you need to paint the exterior of a multi-story building. Using traditional methods, this task would require extensive time, manpower, and scaffolding. However, with the 14m lift, you can effortlessly reach the necessary elevation, significantly reducing the time and resources required.

Construction Applications: In the construction industry, having a large working range is essential for tasks such as steel structure installation, high-level concrete pouring, or installing façade elements like windows and cladding. This lift streamlines these processes, enhancing productivity. For instance, when erecting steel beams for a new building, the 14m lift allows workers to reach elevated connection points efficiently and safely, eliminating the need for costly cranes or scaffolding.

Manufacturing Efficiency: In manufacturing facilities, the 14m lift is invaluable for accessing elevated machinery and workstations. For example, in an automotive assembly line, workers may need to access overhead conveyor systems to perform routine maintenance. The lift's substantial height ensures quick and safe access, reducing downtime and increasing production efficiency.

Maintenance Excellence: Maintenance tasks in various industries often involve reaching elevated equipment or structures. With its 14-meter working range, this lift simplifies these maintenance activities. Consider maintenance in a large warehouse with high shelves. The 14m lift can efficiently transport technicians to the uppermost storage levels, enabling them to service equipment, replace light fixtures, or inspect safety features without the need for complicated scaffolding systems.

Versatile and Cost-Effective: The large working range of the 14m lift makes it a versatile and cost-effective solution for a wide range of applications. Its adaptability across industries helps businesses save time and money by eliminating the need for alternative access methods and reducing labor costs associated with complex setups.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift's substantial working range, reaching 14 meters, offers tangible benefits in terms of time, resources, and safety. It empowers various industries to access elevated areas efficiently, providing practical solutions for tasks that were once labor-intensive or hazardous.

High Elevation

The hydraulic system of this lift ensures high elevation, making it perfect for tasks that require access to elevated structures, machinery, and workstations.

The high elevation capabilities of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift make it an ideal choice for tasks that demand access to elevated structures, machinery, and workstations. Let's delve into specific details and examples to showcase the impressive high elevation capabilities:

Hydraulic System Performance: The hydraulic system of this lift is designed to provide a seamless and controlled ascent to reach substantial elevations. With precise engineering and reliable components, it ensures a safe and steady vertical movement.

Data and Examples

Skyscraper Window Cleaning: When considering the task of cleaning the windows of a skyscraper, the need for high elevation becomes evident. With the 14m lift, window cleaning crews can effortlessly reach even the highest floors without the hassle of suspended scaffolding or swing stages. This translates into significantly reduced labor costs, enhanced safety, and quicker completion of the job.

Warehouse Inventory Management: In large warehouses with towering shelves, inventory management can be a challenge. With the lift's high elevation capacity, workers can efficiently access products stored on upper shelves for inventory checks, restocking, or order fulfillment. This leads to improved inventory accuracy and quicker order processing times.

Power Line Maintenance: Power companies often need to access overhead power lines for maintenance and repairs. The 14m lift's high elevation capabilities make it an invaluable tool for such tasks. For instance, it enables technicians to reach high voltage transmission lines safely, reducing downtime and minimizing service disruptions.

Construction Site Concrete Pouring: In the construction industry, high elevation is crucial for tasks like pouring concrete on upper floors or within tall building structures. The lift allows concrete pump operators to reach the desired height, ensuring a continuous and uniform pour. This enhances construction efficiency and quality.

Maintenance of Elevated Machinery: Manufacturing facilities with tall machinery often require maintenance and repairs at elevated points. The lift's high elevation feature facilitates access to these machinery parts, reducing downtime and ensuring that the equipment remains in optimal working condition.

The high elevation capabilities of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift enable it to excel in a wide range of applications. Whether it's window cleaning on skyscrapers, inventory management in warehouses, power line maintenance, construction tasks, or equipment maintenance, this lift's ability to reach impressive heights enhances efficiency, safety, and overall productivity.

Large Load Capacity

Designed to handle heavy loads, the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift enables you to tackle tasks that involve both personnel and equipment.

The significant load capacity of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is a critical feature that allows it to handle heavy loads effectively. Let's delve into specific details and examples to highlight its impressive load-bearing capabilities:

Load Capacity Data

The 14m lift is engineered to carry a substantial load, with a capacity of up to 500 kilograms (1100 pounds). This robust load capacity sets it apart as a versatile and capable lifting solution.

Examples of Load-Bearing Applications:

Construction Material Transport: In the construction industry, heavy materials like bricks, concrete blocks, and steel beams need to be transported to elevated work areas. The lift's high load capacity enables it to efficiently move these materials, reducing manual labor and expediting construction processes. For instance, a 500-kilogram capacity can easily handle pallets of bricks or bundles of construction materials.

Industrial Equipment Installation: Manufacturing facilities often require the installation of heavy machinery and equipment on elevated platforms. The lift's load capacity allows for the safe and controlled transportation of these machinery components. For instance, during the installation of a heavy CNC machine, the lift can safely hoist and position the equipment in the desired location.

Personnel and Tools: In maintenance and repair tasks that involve both personnel and tools, the lift's load capacity becomes essential. Maintenance crews can carry heavy toolboxes, spare parts, and equipment to elevated work areas without the need for manual lifting. This enhances efficiency and reduces the risk of injury.

High-Altitude Painting and Maintenance: When performing tasks such as high-altitude painting or maintenance on structures like bridges or towers, workers often need to transport heavy paint cans, tools, and equipment to the work site. The lift's load capacity ensures that workers have the necessary tools and materials readily available, streamlining the entire process.

Warehouse Inventory Handling: Warehouses with multi-level racking systems often require the movement of heavy items between storage levels. The lift's load capacity simplifies the process of transferring heavy pallets or crates between different warehouse levels, optimizing inventory management.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift's substantial load capacity, capable of handling up to 500 kilograms, extends its utility to a wide range of applications. Whether it's construction, industrial equipment installation, maintenance tasks, or warehouse operations, this lift's load-bearing capabilities make it an indispensable tool for tackling tasks that involve both heavy loads and personnel.

Hydraulic Tires

The lift is equipped with hydraulic tires, which not only enhance mobility but also operate quietly, and prevent damage to the ground. This feature ensures a longer service life and contributes to a quieter and safer work environment.

The presence of hydraulic tires in the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift plays a significant role in enhancing mobility, minimizing noise, preventing ground damage, and contributing to a longer service life. Here are the details and examples to illustrate the advantages of hydraulic tires:

Hydraulic Tires Data

The lift is equipped with hydraulic tires designed to support its weight and facilitate easy movement. These tires are engineered to reduce friction, allowing for smoother and quieter operation. The precise specifications of these tires may vary by manufacturer, but they are typically designed for durability and load-bearing capacity.

Examples of Benefits and Applications:

Enhanced Mobility: Hydraulic tires are pivotal in improving the lift's mobility. They allow it to be moved around a worksite with ease, both indoors and outdoors. For instance, in a construction project, the lift can be effortlessly maneuvered to access different areas, eliminating the need for time-consuming dismantling and reassembly. The mobility of the lift significantly accelerates task completion.

Quiet Operation: One of the notable advantages of hydraulic tires is their ability to operate quietly. In industrial and commercial settings, noise reduction is a crucial factor for maintaining a productive and comfortable work environment. The low-noise operation of the lift ensures that workers can focus on their tasks without disruptions, and it minimizes disturbances to nearby areas, such as offices or residential neighborhoods.

Ground Protection: Hydraulic tires are designed to distribute the lift's weight evenly, reducing the impact on the ground surface. This is particularly beneficial when operating in environments where floor or ground damage must be minimized. For example, when using the lift on a polished concrete floor in a warehouse or showroom, the hydraulic tires prevent scuffs, scratches, or indentation, preserving the floor's aesthetics and safety.

Longer Service Life: The combination of hydraulic tires that reduce wear and tear on the lift's components and the prevention of ground damage leads to a longer service life for the equipment. The reduced strain on the lift's mechanical parts contributes to its durability and longevity, resulting in a cost-effective investment for businesses.

Safety and Stability: Hydraulic tires provide a stable and secure base for the lift, ensuring that it remains level and safe during operation. This stability is vital when the lift is used to elevate personnel to significant heights, as it minimizes the risk of accidents due to uneven or unstable ground.

The inclusion of hydraulic tires in the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift offers multiple advantages. These tires enhance mobility, reduce noise, protect the ground surface, promote a longer service life, and contribute to a safer and quieter work environment. Whether it's construction, maintenance, or industrial applications, hydraulic tires ensure that the lift operates efficiently and effectively.

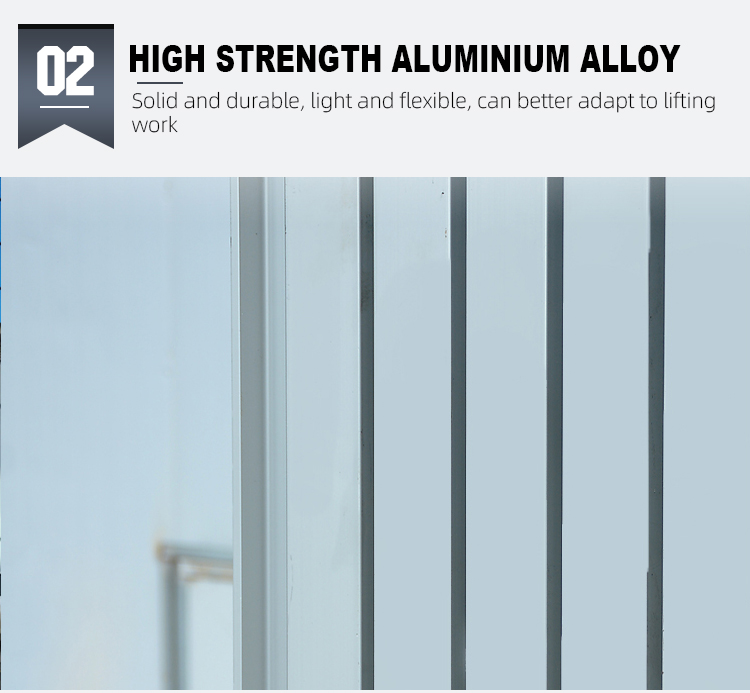

Durable Aluminum Alloy

Crafted from high-strength aluminum alloy, this lift is not only lightweight but also boasts a significantly extended service life. This combination of lightweight construction and durability guarantees your safety and efficiency.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift's construction from high-strength aluminum alloy offers several significant advantages, including durability, lightweight design, and extended service life. Here are the details and examples to highlight these benefits:

High-Strength Aluminum Alloy Data

The lift is constructed using a high-strength aluminum alloy, which provides a winning combination of strength and reduced weight. The specific alloy used may vary, but it is designed to withstand rugged usage and support the lift's structural integrity.

Examples of Benefits and Applications:

Lightweight Design: The use of high-strength aluminum alloy results in a lightweight lift, making it easy to transport and maneuver. For instance, in a scenario where you need to move the lift between different work areas in a facility, its lightweight design simplifies the process. Workers can efficiently load it onto a truck or trailer, reducing the need for heavy machinery or multiple personnel to move it.

Extended Service Life: Aluminum alloy is known for its corrosion resistance and durability. The lift's components are less prone to rust and wear, ensuring a longer service life. In a coastal environment, where exposure to saltwater and moisture is high, the lift's aluminum alloy construction helps maintain its structural integrity over time, reducing maintenance and replacement costs.

Safety and Stability: The combination of a lightweight structure and high-strength aluminum alloy contributes to the lift's overall safety and stability. When the lift is elevated to its maximum height, a durable construction is critical for ensuring that it remains secure and balanced. This is especially important when the lift is used to transport personnel, ensuring their safety during tasks at elevation.

Transportation Efficiency: The lightweight design of the lift not only eases its movement within a worksite but also reduces transportation costs. When shipping the lift between different locations, the lower weight minimizes fuel consumption and transportation expenses. It also simplifies the process of loading and unloading the lift from delivery vehicles.

Versatility and Accessibility: The lift's lightweight yet durable construction enhances its versatility. It can be used in various indoor and outdoor applications, including construction sites, warehouses, manufacturing facilities, and more. Its reduced weight also ensures that it can access elevated areas where heavier equipment might not be suitable.

The use of high-strength aluminum alloy in the construction of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift offers a multitude of benefits. Its lightweight design enhances mobility and transportation efficiency, while its durability and corrosion resistance ensure a longer service life. These factors collectively guarantee safety, efficiency, and cost-effectiveness across various industries and applications.

Safety First

The lift is designed with safety as a top priority. It features an emergency button that, in case of an unexpected situation, allows the lift to be safely and steadily lowered, ensuring the well-being of your operators.

"Safety First" is a crucial aspect of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift's design. The presence of safety features, such as an emergency button, underscores its commitment to ensuring the well-being of operators. Here are the details and examples highlighting the safety measures of this lift:

Safety Features Data

The 14m lift is equipped with a prominent emergency button that is easily accessible to the operator. When activated, this button initiates a process that safely and steadily lowers the lift to the ground, even in unexpected or emergency situations.

Examples of Safety Benefits

Emergency Situations: In any work environment, there may be unforeseen circumstances that pose a risk to operators working at elevation. Examples include sudden equipment malfunctions, medical emergencies, or adverse weather conditions. In these cases, the presence of an emergency button is crucial. For instance, if an operator suddenly feels unwell while elevated on the lift, pressing the emergency button ensures their safe and controlled descent to the ground, allowing for immediate medical attention if needed.

Mechanical Failures: Despite regular maintenance, equipment can experience unexpected mechanical failures. The emergency button acts as a fail-safe mechanism in such situations. If, for instance, there is an unexpected malfunction in the lift's control system, the operator can swiftly initiate the emergency descent, avoiding any risk of an uncontrolled or unsafe drop.

Power Outages: Power interruptions or electrical failures can occasionally occur in industrial settings. If the lift is in an elevated position during a power outage, the emergency button allows operators to initiate a safe descent, preventing any discomfort or panic among personnel.

Storms and High Winds: Adverse weather conditions, such as strong winds or thunderstorms, can pose risks to operators on elevated lifts. In such scenarios, the emergency button provides a quick and secure means of lowering the lift to a safe position on the ground, protecting both personnel and equipment.

Operator Training: The presence of an emergency button also contributes to operator training and safety awareness. Operators are trained to recognize when and how to use this safety feature, adding an additional layer of preparedness to mitigate risks during their work.

The safety-first approach of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is evident in its emergency button feature. This feature ensures that in case of unexpected or emergency situations, operators can take immediate action to lower the lift safely and steadily to the ground, preventing accidents, injuries, and ensuring the overall well-being of the personnel working at elevation.

Ease of Use

The intuitive controls make operating the lift a breeze, reducing the learning curve for your staff. It's faster, safer, and more efficient to use, ultimately enhancing your productivity.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is designed with ease of use in mind. Its intuitive controls streamline operation, making it user-friendly and reducing the learning curve for staff. Here are the details and examples that illustrate the advantages of this user-friendly design:

Ease of Use Data

The lift is equipped with a user-friendly control panel that includes straightforward buttons and functions. The design of the controls prioritizes ease of operation and is optimized for efficiency and safety.

Examples of Ease of Use Benefits:

Quick Start: The lift's control panel is designed for quick and easy startup. For instance, a single push of a button can activate the lift's hydraulic system and initiate the ascent. This streamlined process minimizes delays and allows operators to get to work promptly.

Efficient Positioning: The intuitive controls enable precise and efficient positioning of the lift. Operators can easily adjust the lift's height or move it horizontally as needed. For instance, when conducting maintenance on a complex piece of machinery, operators can effortlessly position the lift to the required height and reach all the necessary components without hassle.

Smooth Operation: The user-friendly controls ensure smooth and controlled operation. This is especially important when the lift is used to transport personnel or sensitive equipment. For example, if the lift is employed in a film production setting for lighting and camera adjustments, the easy-to-use controls allow for precise positioning, minimizing the time and effort required for adjustments.

Safety Features: The user-friendly design includes safety features, such as the emergency button mentioned earlier. These features are seamlessly integrated into the control panel and are easily accessible to operators. This ensures that even in emergency situations, operators can act swiftly and confidently to guarantee their safety.

Reduced Training Time: The intuitive controls significantly reduce the learning curve for operators. Training can be completed more efficiently, allowing new personnel to become proficient in lift operation in a shorter time frame. This results in a faster adaptation to the equipment and an accelerated productivity rate.

The ease of use of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is achieved through its user-friendly control panel and intuitive design. This makes it quicker and simpler for operators to learn and operate the lift effectively. The efficient operation enhances productivity, allowing operators to complete tasks with speed and precision, whether it's in construction, maintenance, industrial applications, or other work settings.

OEM Factory Quality

This product is built to exacting OEM factory standards, guaranteeing reliability and performance.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is manufactured to precise OEM (Original Equipment Manufacturer) factory standards, ensuring unrivaled reliability and performance. Here are the details and examples that highlight the benefits of this commitment to quality:

OEM Factory Quality Data

The lift is constructed with strict adherence to the quality standards established by the original equipment manufacturer, guaranteeing consistency, durability, and top-tier performance. These standards encompass the selection of materials, manufacturing processes, quality control, and safety measures.

Examples of OEM Factory Quality Benefits

Reliability: By adhering to OEM factory standards, the lift achieves a level of reliability that is second to none. This translates to fewer breakdowns and less downtime, ultimately leading to increased productivity. For instance, in a busy warehouse with tight schedules, a reliable lift ensures that tasks are completed on time without costly interruptions.

Performance Consistency: The product's strict adherence to OEM factory standards ensures consistency in performance. Whether you have one lift or a fleet of them, you can expect uniform performance across all units. This consistency is invaluable when working on projects that require multiple lifts to operate in synchronization, such as large-scale construction projects or event setups.

Quality Materials: The use of high-quality materials, including the aforementioned high-strength aluminum alloy, enhances the longevity and performance of the lift. For example, a lift used in an outdoor construction project will endure harsh weather conditions, and the use of quality materials ensures it remains operational in spite of exposure to the elements.

Safety Assurance: OEM factory standards encompass stringent safety measures. This includes the integration of safety features, rigorous testing, and quality control. For instance, during the manufacture of the lift, every safety component is tested and verified to meet the highest safety standards, ensuring that operators and personnel are protected during use.

Reduced Maintenance Costs: The commitment to quality results in a lift that is less prone to breakdowns and wear and tear. This translates into reduced maintenance costs over its operational life. For a manufacturing facility, lower maintenance expenses free up resources that can be directed toward other critical aspects of production.

The adherence to OEM factory standards in the manufacturing of the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift guarantees unparalleled reliability and performance. This consistency is crucial for diverse applications, from construction to manufacturing to maintenance, ensuring that operators can rely on the lift for efficient and dependable operation, minimizing downtime, and reducing long-term costs.

Low Maintenance

With quality components and materials, this lift requires minimal maintenance, resulting in cost savings over its lifespan.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift is designed to be low maintenance, which translates into significant cost savings over its lifespan. Here are the details and examples to highlight the benefits of its low-maintenance design:

Low Maintenance Data

The lift is constructed using high-quality components and materials that are selected for their durability and resistance to wear and tear. These components are designed to minimize the need for frequent maintenance and repairs.

Examples of Low Maintenance Benefits

Extended Service Life: The use of quality components and materials ensures the lift's longevity. For example, the lift's hydraulic system is designed to resist wear and provide consistent performance over an extended period. As a result, operators can rely on the lift for many years without facing the costs associated with frequent replacements.

Reduced Downtime: With low-maintenance requirements, the lift is less likely to experience unexpected breakdowns or malfunctions. This reduces downtime, particularly in critical industries like manufacturing and construction, where every minute of operational time is valuable. For example, in manufacturing, where a production line relies on the lift for material handling, reduced downtime keeps the workflow smooth and uninterrupted.

Minimized Repair Costs: Low-maintenance equipment typically requires fewer repairs. This translates into cost savings on spare parts, labor, and repair services. In the long run, these savings contribute to a more cost-effective investment. For instance, in a construction project where the lift is used for tasks like steel structure installation, fewer repair expenses lead to a more profitable project.

Efficient Use of Resources: Low-maintenance equipment frees up resources that would otherwise be allocated to frequent servicing and repairs. These resources can be redirected to other critical areas, such as operator training, safety enhancements, or the acquisition of additional equipment. For example, in a warehouse setting, the reduction in maintenance needs allows businesses to invest in expanding their inventory or improving logistics.

Reliability in Varied Environments: The low-maintenance design ensures that the lift remains operational even in challenging environments. For instance, if the lift is used in outdoor construction projects where it is exposed to harsh weather conditions, the quality components and materials prevent excessive wear and damage, resulting in consistent performance.

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift's low-maintenance design, which relies on high-quality components and materials, offers numerous advantages. It extends the service life, reduces downtime, lowers repair costs, and promotes the efficient use of resources. This ensures that the lift remains reliable and cost-effective in various industries and applications, ultimately leading to substantial cost savings over its operational lifespan.

Applications

The 14m OEM Factory Portable Vertical Hydraulic Mobile Aluminum Alloy Four Mast Lift is suitable for various industries, including:

Construction: Ideal for reaching high structures, facilitating painting, repairs, and installation tasks.

Manufacturing: Streamline your production processes by accessing elevated machinery and workstations with ease.

Maintenance: Simplify equipment servicing and building upkeep by reaching challenging locations safely.

Secure Packaging

We understand the importance of delivering your investment in pristine condition. That's why we ensure the safety of your goods by packing the lift in wooden boxes. Rest assured that your equipment will arrive at your doorstep in perfect condition.

Conclusion

The 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift with its large working range, high elevation capabilities, and substantial load capacity is a game-changer for your business. Its light weight and extended service life, along with advanced safety features, ensure both your efficiency and safety. Whether it's for construction, manufacturing, or maintenance, this lift is the versatile solution you've been looking for.

With hydraulic tires for ground protection and an emergency button for unforeseen situations, it's the complete package. The secure packaging ensures that your equipment arrives in perfect condition. So why wait? Elevate your operations today with the 14m OEM factory portable vertical hydraulic aluminum alloy four mast lift. Contact us now for inquiries and make your work environment more efficient and safer.

FAQ

1. What is the maximum working height of the 14m OEM Factory Portable Vertical Hydraulic Mobile Aluminum Alloy Four Mast Lift?

The maximum working height of this lift is 14 meters or approximately 46 feet.

2. What industries and applications is this lift suitable for?

This lift is suitable for a wide range of industries, including construction, manufacturing, maintenance, warehousing, and more. It can be used for tasks like construction work, equipment installation, inventory management, high-altitude maintenance, and more.

3. How much weight can this lift carry?

The 14m lift is designed to handle heavy loads with a capacity of up to 500 kilograms (approximately 1100 pounds). This makes it suitable for transporting both personnel and equipment.

4. Does the lift come with safety features?

Yes, safety is a top priority. The lift is equipped with an emergency button that allows for a safe and steady descent in case of unexpected situations or emergencies. Additionally, it complies with safety standards to ensure operator well-being.

5. Can the lift be used indoors and outdoors?

Yes, the lift is designed for versatility and can be used both indoors and outdoors. Its mobility and robust construction make it suitable for various environments.

6. How does the lift's hydraulic system operate?

The hydraulic system of the lift ensures smooth and controlled vertical movement. It is designed for stability and safety during elevation and descent.

7. Is the lift user-friendly and easy to operate?

Yes, the lift features intuitive controls that make it easy to operate. This reduces the learning curve for operators, resulting in quicker adaptation and improved productivity.

8. What are the maintenance requirements for this lift?

The lift is designed with quality components and materials to minimize maintenance needs. This translates to cost savings over its lifespan. Regular maintenance, such as inspections and lubrication, is recommended to ensure optimal performance.

9. How is the lift packaged for delivery?

The lift is packaged in wooden boxes to ensure the safety of the goods during transportation to your location. This packaging helps protect the lift from damage.

222.webp)

660.webp)